• Engineering system design and supplies

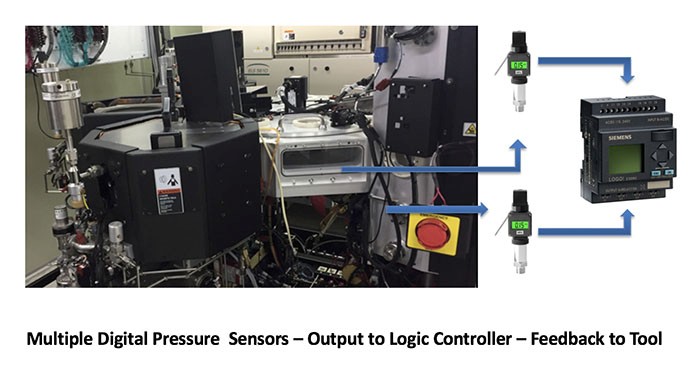

• User friendly, programmable system

• Defects/Scraps prevention projects

• Includes electrical, mechanical and fluid systems

• Customized to fit requirements

• Wet Cart System and Heated Bench System for

MEMC/SunEdison

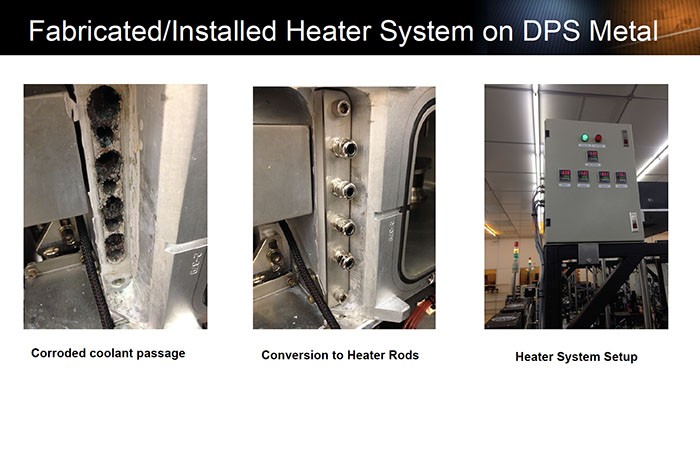

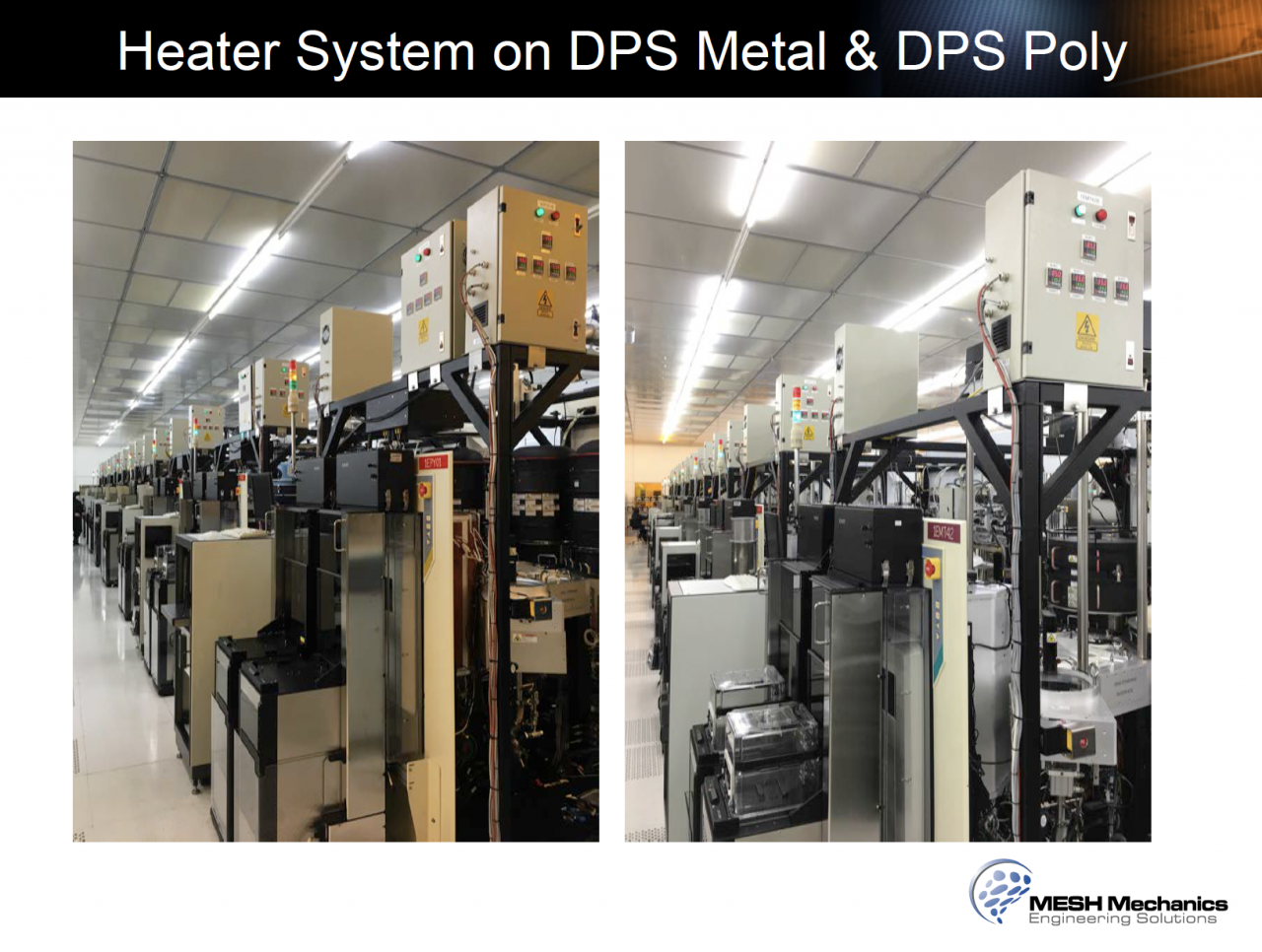

• Heater System for Etch DPS Metal System (Chiller to

Dry Heater System conversion)

Flowmeter Upgrade – From analog to digital with Temperature Monitoring and Interlock

• Complete dry system – zero fluid/coolant leakage

• Eliminate potential shock hazards & electrical system failure due to fluid leakage

• Equipment downtime on chiller maintenance/swap

• Energy consumption savings of approx 56.3% comparing to existing NESLAB Steelhead 0 Chillers.

• 34.8kWh/79.5kWh = 43.7% of power consumed by existing chillers.

• Summary : 56.3% energy savings exclusive of chiller repair/maintenance

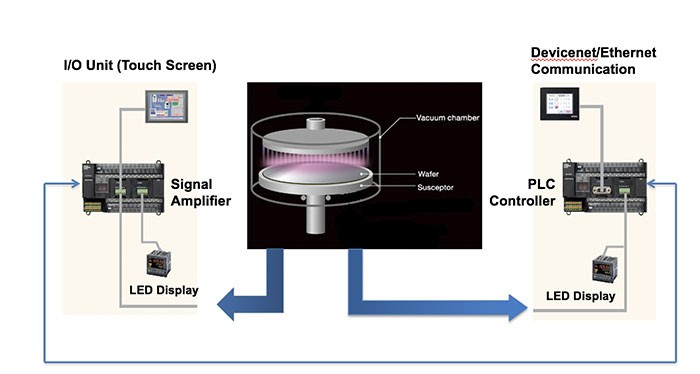

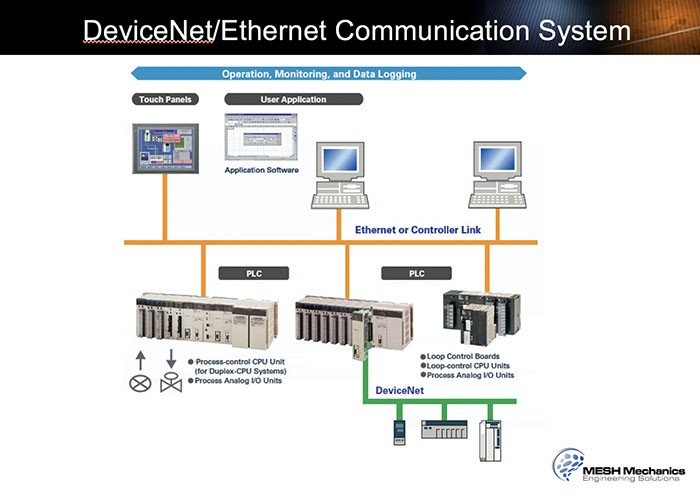

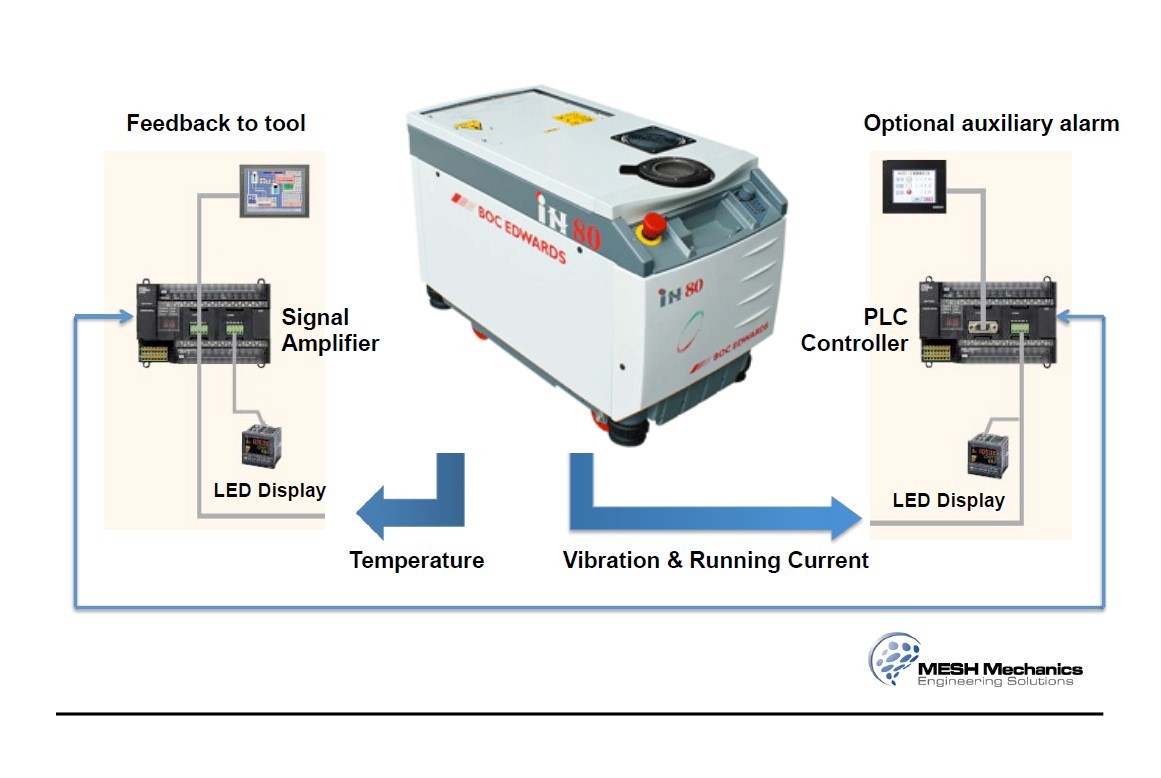

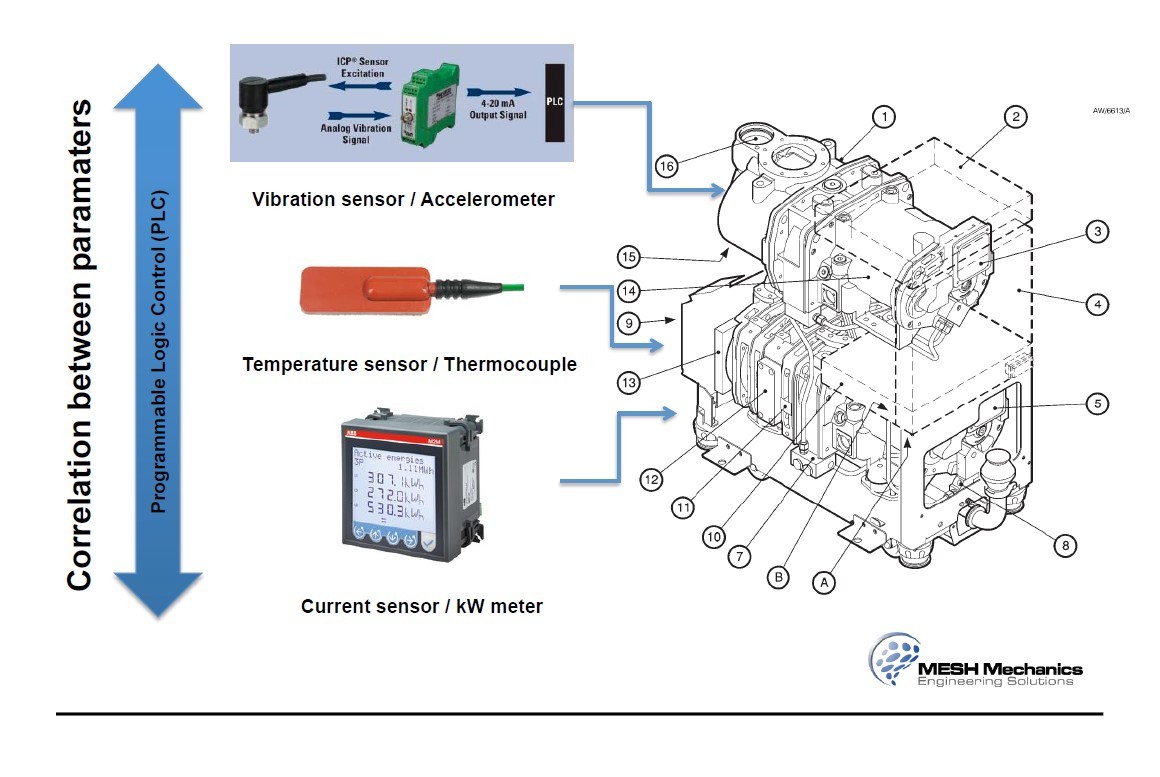

• Continuous monitoring of input devices and decision making based upon custom program to control the state of output devices

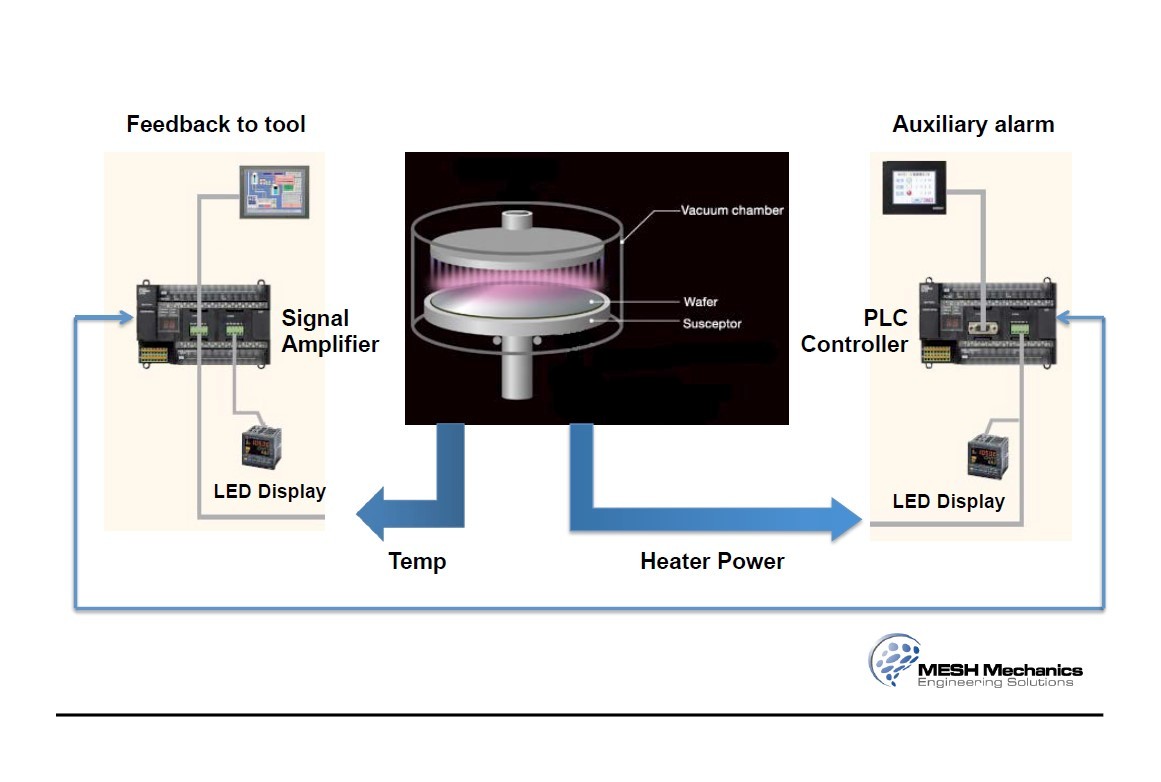

• Complete system to monitor both heater temperature and heater element power consumption at susceptor

• Independent system, not interfering with existing OEM system configurations

• Configured alarm system that feedbacks to OEM tool

• Highly visible LED display of current temperature, OEM tool temperature and alarm status

Cart System Fabrication – Stainless Steel and Plastic Welding